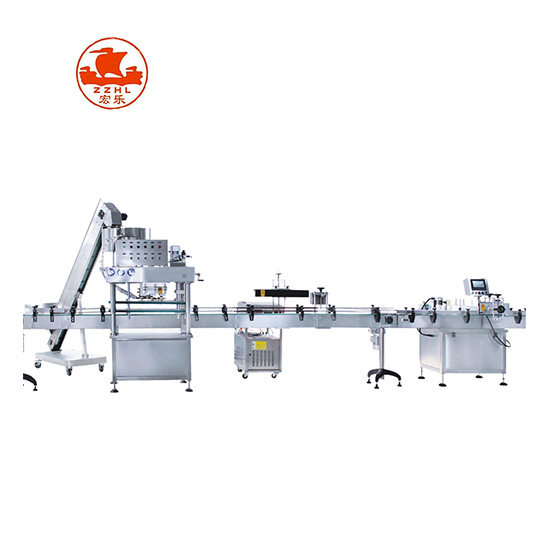

| No | Picture | Parameter &Name |

| 1 |  |

Name:Bottle unscrambler

Suitable for bottle size diameter:φ20mm~φ100mm Height:20mm~150mm Voltage:220V Machine size L*W*H:990*900*1040mm |

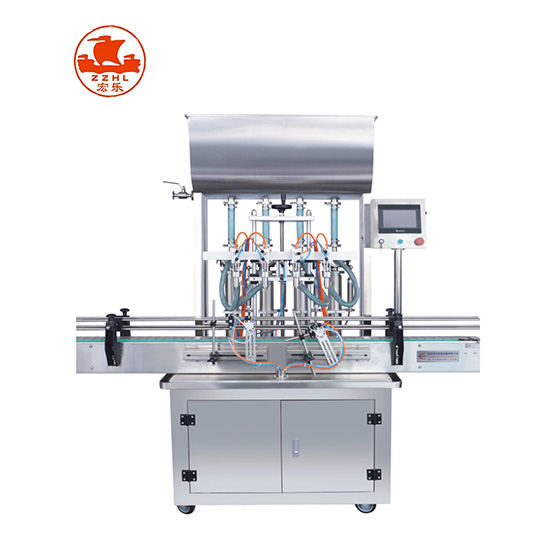

| 2 |  |

Name:Automatic Liquid Filling Machine

Filling heads:4 Bottle Diameter:≥50mm Filling range:500-2500 ml(can customize) Filling accuracy:±1% Filling speed:1000-1200 bottles/h Air pressure:0.4-0.6MPa Required Air Compressor:≥7.5kw 200L Total power:400W Weight:480 kg Size(L*D*H):2000*1050*1650mm |

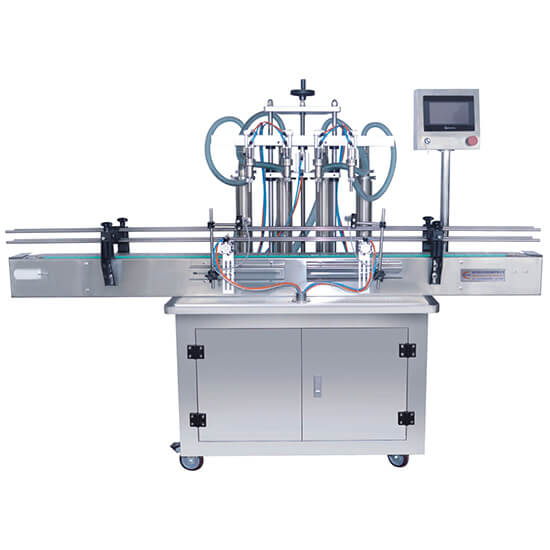

| 3 |  |

Name:Automatic linear capping machine

Suitable bottle size:φ35-φ110 H150-300mm Suitable cap diameter:32-80mm Work speed:20-25bottles/min Voltage :220V 50HZ Power:750W Working air source:0.6~0.8MPa Weight:268KG Size:2000*1400*1400mm |

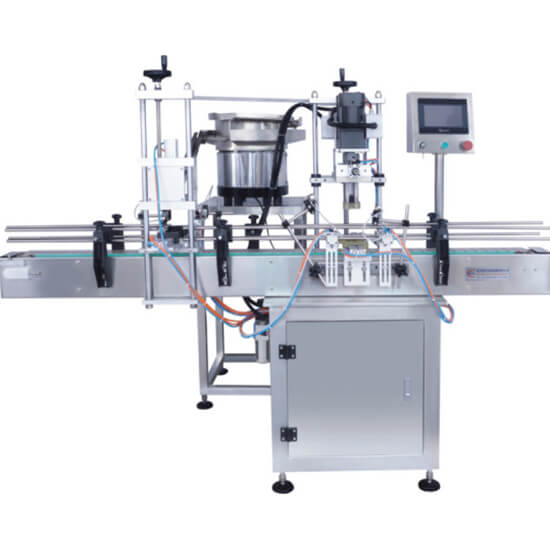

| 4 |  |

Name:Automatic round bottle labeling machine

Labeling Speed :10-30 bottles/min Bottle Diameter:Φ30-100mm Label Size:H20-300mm W30-150mm External Dia of Paper Roll:≤φ260mm Inside Dia of Paper Roll:≥φ75mm Required Air Compressor0.4-0.6Mpa Valtage :220V Power:200W Weight:150KG Size:2000*800*1400mm |

1. J Rotary Bottle Feeding Machine

This machine adopts frequency control for rotary motion, the bottle in the rotary tangential force in order to enter the conveyor belt, supporting and packaging production lines, save labor, improve efficiency, applicable range of 50-1000ml container glass bottles, plastic bottles, plastic bottle, etc.

The main parts of this machine are made of high quality stainless steel and meet the requirements of GMP.

2. Automatic Liquid Filling Machine

Features :

Automatic liquid filling machine is made with electric,mechanical and pneumatic principle. Use counter to control the filling volume and designed with Special filling nozzle to reduce bubble when filling.

It is widely use for foodstuff chemical and medicine filed etc. We can accord to customer's requirements to design the filling volume.

Performance Characteristics :

1. Can customize products according to customer bottle samples.

2. Adopted piston quantitative, mechanical and electrical, pneumatic in one, electrical and pneumatic components used well-known brands.

3. Screen rational design, simple operation.

4. Compact structure, beautiful appearance, with stable and reliable performance, easy maintenance.

5. Filling accuracy,adaptability.

3. Automatic linear capping machine

Equipment Usage :

Linear duckbill Capping machine suitable for different size of caps and bottles, screw power and rotation speed of screw capping machine is adjustable.

It is widely apply to pharmaceutical, chemical, food, beverage, grease and pesticide industry.

Features :

1. With features like ease of operation, highly productive and competitive price etc.

2. This machine can be operated alone or coupled with filling machine, make the formation of filling line possible.

4. Automatic round bottle labeling machine

Equipment Usage :

Automatic Labeling Machine can meet the needs of all round bottle labeling or semi circle labeling, bottle labeling switching between simple, convenient adjustment;

Wide application range: self-adhesive labels, adhesive film, electronic monitoring code, bar code etc.

Application Industry: widely used in food, medicine, cosmetics, daily chemical, electronics, hardware, plastics and other industries.

Application example: PET round bottle labeling, plastic bottle labeling, canned food, etc.

Features :

1.Three rollers fixing labeling device, make label close-fitting.labeling smooth, no wrinkles, improve packaging quality.

2.Flexible application, bottle stand vertical labeling, with automatic sub bottle function, can be stand-alone production, can also be connected to the production line.

3. Intelligent control, automatic photoelectric tracking, with no matter no labeling, no standard automatic calibration and label automatic detection function, prevent leakage and label waste.

4. High stability, PLC+ touch screen + needle + Electric eye Leuze label consisting of senior electric eye control system.

5. Simple adjustment, labeling speed, conveying speed, bottle speed can be achieved stepless speed regulation, according to the need to adjust.

6.Durable, using three bar adjustment mechanism, make full use of triangular stability, solid durable machine. Made of stainless steel and advanced aluminum alloy, accord with CE Production requirements.

Note: Standard machine can only be used normal round bottles , can not be too soft or bulge, can be modified if the bottle has grooves.

-

This machine is equipped with a dual-CPU microcomputer control system, a 5-inch LCD display in Chinese or English, a humanized operation interface, automatic cursor detection and tracking, and simpler operation. Equipped with a high-precision stepping motor to ensure the accuracy of the cutting position of each packaging bag.

This machine is equipped with a dual-CPU microcomputer control system, a 5-inch LCD display in Chinese or English, a humanized operation interface, automatic cursor detection and tracking, and simpler operation. Equipped with a high-precision stepping motor to ensure the accuracy of the cutting position of each packaging bag.

280 350 Model Automatic Powder Packing Machine

-

PLC control with stable reliable biaxial high accuracy output and color touch screen, bag-making, measuring, filling, printing,cutting , finished in one operation.

PLC control with stable reliable biaxial high accuracy output and color touch screen, bag-making, measuring, filling, printing,cutting , finished in one operation.

520 Type Automatic Powder Packing Machine

-

Applicable scope for packaging milk powder, sesame paste, strong bone powder, condiments, Ganoderma lucidum powder, granules and other items.

Applicable scope for packaging milk powder, sesame paste, strong bone powder, condiments, Ganoderma lucidum powder, granules and other items.

HL-GDF Full Automatic Powder Filling and Packing Machine

-

Suitable for quantitative filling of various bottles, cans and bags,Photoelectric induction blanking, or optional foot switch blanking,Feedback scale and indexing value can be adjusted to meet various accuracy requirements.

Suitable for quantitative filling of various bottles, cans and bags,Photoelectric induction blanking, or optional foot switch blanking,Feedback scale and indexing value can be adjusted to meet various accuracy requirements.

Semi-automatic Powder Packaging Machine

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.